- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Hot: Umbrella Valve, Duckbill Valve, Flapper Valve, Silicone Valve & Rubber One Way Valve

| Availability: | |

|---|---|

| Quantity: | |

Rubber Transfer Molding for Silicone Membrane Valve

Rubber Transfer Molding for Silicone Membrane Valve, also known as Silicone Transfer Molding for Rubber Membrane Valve, Silicone Membrane Gasket, Silicone Membrane Seal, which is similar to compression molding, in that a carefully calculated, pre-measured amount of uncured molding silicone rubber is used for the molding process. Transfer molding is a great way to create composite seals with insert molding — which “float” in the cavity. Since cavities are independent of one another, they can move freely rather than being cut directly into the same plate. Rubber Transfer Molding can be used for producing Silicone Membrane valves ( Rubber Membrane Valves, Membrane Gasket, Membrane Seals), it consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal. Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

Silicone Membrane Valve can be make with various inserts like plastic, metal and glass can be used to make the composite seal. These allow for a multi-component sealing solution, helping reduce overall component count in assembly and providing a more robust seal.

Transfer molding efficiently creates a wide variety of lightweight and durable rubber products, like silicone membrane, membrane gaskets, membrane seals, etc.

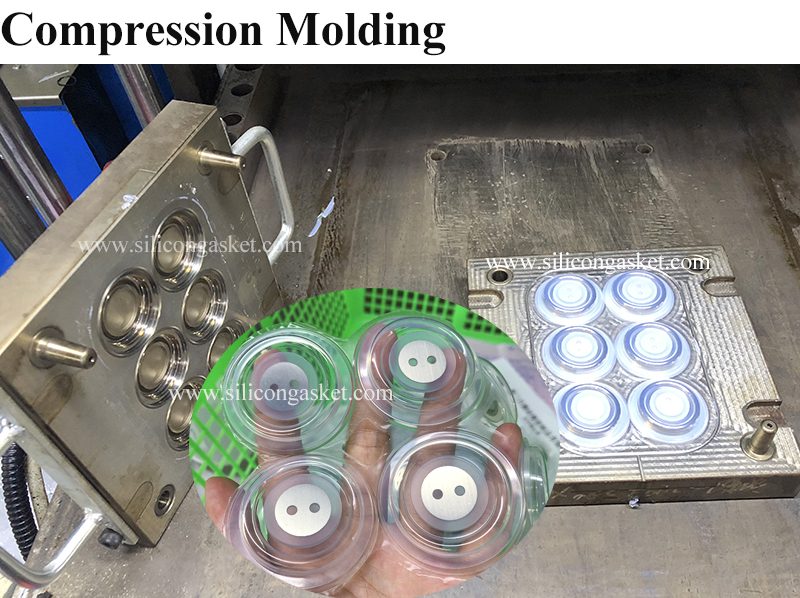

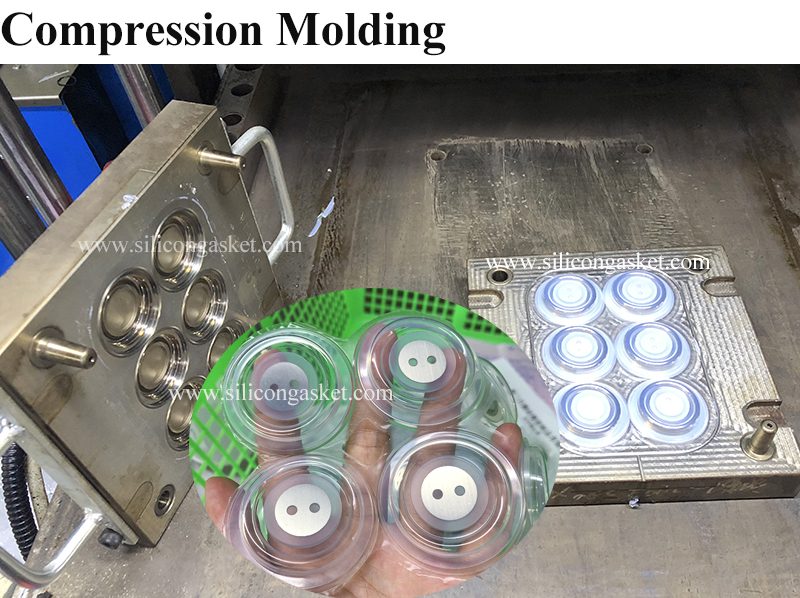

Rubber Transfer Molding for Silicone Membrane Valve Design Guide is similar to Silicone Compression Molding for Rubber Membrane Gasket. The difference is, instead of put the material into an open mold, the silicone rubber material is pre-heated and loaded into a holding chamber called the pot. There is a pot on the top plate and a ram above the pot. This mold pot is used to contain pre-measured silicone rubber raw material and transfer it into the cavities through pot runners and sprues. The mold remains closed until the material inside is cured, while compression molding is low cost molding process than the transfer molding.

Rubber Transfer Molding for Silicone Membrane Valve Production Process

Today there are some customers asking if it is a good solution that steel plate bonded with glue in the center of the Silicone Membrane Valve.

and the main function of the steel plate is to make the center surface stiff, but also to make a durable surface.

Watch the followed video, then you'll find out the best solution:

1. Smearing a small amount of glue on the steel/ metal plate

2. Fixing the steel/ metal plate on the Silicone Membrane Mold, then put the silicone material on it.

3. Closing the mold and start the molding process for about 350 seconds.

Rubber Transfer Molding for Silicone Membrane Valve Advantages

More Precise with Minimum Flash: Rubber Transfer molded silicone membrane valve inherently have less flash (excess material that runs along the parting line of the mold) than their compression molded membrane valve because the mold remains closed when the material enters the mold cavity.

Mold with More Cavity: Rubber Transfer molding silicone rubber membrane seal require few and simple prepared material. One prepared material can fill many cavities. Compare with silicone compression molding, it is an advantage and can save a significant amount of time in the molding process, which is also an advantage over injection molding since there is not a runner to fill each cavity.

Allow Different Materials of Inserts: One of the key advantages of transfer molding over compression molding is that different inserts, such as metal parts, plastic chips, dry composite fibers, ceramics, etc., can be placed/positioned in the mold cavity before the material is injected into the cavity. This ability makes transform molding the leading manufacturing process for integrated circuit packaging and electronic components with molded terminals, pins, studs, connectors, and so on.

Short Production Cycle: Silicone Rubber Transfer Molding Membrane Gasket offers shorter cycle times than compression molding and can also provide more consistency. The process allows for tighter tolerances and more intricate parts.

Rubber Transfer Molding for Silicone Membrane Valve Disadvantages

Material Waste: However, Rubber Transfer Molding produces more waste material than compression molding because of the sprue, the air holes and the overflow grooves that are often needed to allow air to escape and material to overflow.

Mold is more expensive than compression mold: because the design and mold is more complex, therefore tooling can also become expensive.

Production speed: It is lower than injection molding

Rubber Membrane Valve Material

Rubber Membrane Valves/ Diaphragm Valves can be made from a variety of materials. The material choice is based on the nature of the material handled, temperature, pressure, and frequency of operation. Elastomeric diaphragm materials are highly resistant to chemicals at high temperatures. However, the mechanical properties of elastomeric materials will be weakened at a higher temperature (above 150°F). High pressure can also destroy the diaphragm. Another factor that can affect the diaphragm function is the concentration of the media it will handle. The material may exhibit satisfactory corrosion resistance to certain corrodents up to a specific concentration and/or temperature. Examples of diaphragm material and their specifications can be seen in the chart below.

Rubber Transfer Molding for Silicone Membrane Valve

Rubber Transfer Molding for Silicone Membrane Valve, also known as Silicone Transfer Molding for Rubber Membrane Valve, Silicone Membrane Gasket, Silicone Membrane Seal, which is similar to compression molding, in that a carefully calculated, pre-measured amount of uncured molding silicone rubber is used for the molding process. Transfer molding is a great way to create composite seals with insert molding — which “float” in the cavity. Since cavities are independent of one another, they can move freely rather than being cut directly into the same plate. Rubber Transfer Molding can be used for producing Silicone Membrane valves ( Rubber Membrane Valves, Membrane Gasket, Membrane Seals), it consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal. Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

Silicone Membrane Valve can be make with various inserts like plastic, metal and glass can be used to make the composite seal. These allow for a multi-component sealing solution, helping reduce overall component count in assembly and providing a more robust seal.

Transfer molding efficiently creates a wide variety of lightweight and durable rubber products, like silicone membrane, membrane gaskets, membrane seals, etc.

Rubber Transfer Molding for Silicone Membrane Valve Design Guide is similar to Silicone Compression Molding for Rubber Membrane Gasket. The difference is, instead of put the material into an open mold, the silicone rubber material is pre-heated and loaded into a holding chamber called the pot. There is a pot on the top plate and a ram above the pot. This mold pot is used to contain pre-measured silicone rubber raw material and transfer it into the cavities through pot runners and sprues. The mold remains closed until the material inside is cured, while compression molding is low cost molding process than the transfer molding.

Rubber Transfer Molding for Silicone Membrane Valve Production Process

Today there are some customers asking if it is a good solution that steel plate bonded with glue in the center of the Silicone Membrane Valve.

and the main function of the steel plate is to make the center surface stiff, but also to make a durable surface.

Watch the followed video, then you'll find out the best solution:

1. Smearing a small amount of glue on the steel/ metal plate

2. Fixing the steel/ metal plate on the Silicone Membrane Mold, then put the silicone material on it.

3. Closing the mold and start the molding process for about 350 seconds.

Rubber Transfer Molding for Silicone Membrane Valve Advantages

More Precise with Minimum Flash: Rubber Transfer molded silicone membrane valve inherently have less flash (excess material that runs along the parting line of the mold) than their compression molded membrane valve because the mold remains closed when the material enters the mold cavity.

Mold with More Cavity: Rubber Transfer molding silicone rubber membrane seal require few and simple prepared material. One prepared material can fill many cavities. Compare with silicone compression molding, it is an advantage and can save a significant amount of time in the molding process, which is also an advantage over injection molding since there is not a runner to fill each cavity.

Allow Different Materials of Inserts: One of the key advantages of transfer molding over compression molding is that different inserts, such as metal parts, plastic chips, dry composite fibers, ceramics, etc., can be placed/positioned in the mold cavity before the material is injected into the cavity. This ability makes transform molding the leading manufacturing process for integrated circuit packaging and electronic components with molded terminals, pins, studs, connectors, and so on.

Short Production Cycle: Silicone Rubber Transfer Molding Membrane Gasket offers shorter cycle times than compression molding and can also provide more consistency. The process allows for tighter tolerances and more intricate parts.

Rubber Transfer Molding for Silicone Membrane Valve Disadvantages

Material Waste: However, Rubber Transfer Molding produces more waste material than compression molding because of the sprue, the air holes and the overflow grooves that are often needed to allow air to escape and material to overflow.

Mold is more expensive than compression mold: because the design and mold is more complex, therefore tooling can also become expensive.

Production speed: It is lower than injection molding

Rubber Membrane Valve Material

Rubber Membrane Valves/ Diaphragm Valves can be made from a variety of materials. The material choice is based on the nature of the material handled, temperature, pressure, and frequency of operation. Elastomeric diaphragm materials are highly resistant to chemicals at high temperatures. However, the mechanical properties of elastomeric materials will be weakened at a higher temperature (above 150°F). High pressure can also destroy the diaphragm. Another factor that can affect the diaphragm function is the concentration of the media it will handle. The material may exhibit satisfactory corrosion resistance to certain corrodents up to a specific concentration and/or temperature. Examples of diaphragm material and their specifications can be seen in the chart below.

Home | About Us | Contact Us | Products | News Center | LSR Injection Molding | Liquid Silicone Rubber | Silicone Bellows | Silicone Cover | Silicone Grommet | Silicone Nozzle | Silicone Plug | Silicone Sleeves | Sitemap | Silicone Keypad | Duckbill Valve | Umbrella Valve | Slit Valve | Membrane Valve | News | Silicone Valve | Rubber Valves Manufacturing Process | Silicone Valve Manufacturing Process | Request Quote | Silicone Rubber Sleeve | EPDM Grommet | Nitrile Grommet | Antibacterial Silicone | Silicone Suction Cup | Silicone Sleeve for Glass Bottle | One Way Rubber Valve | Rubber Duckbill Valve | Rubber Flapper Valve | Rubber Mushroom Valve | Company news | Profession news | Frequently Q&A | Liquid Silicone Rubber | silicone sleeve | Product inquiry