- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Hot: Umbrella Valve, Duckbill Valve, Flapper Valve, Silicone Valve & Rubber One Way Valve

| Availability: | |

|---|---|

| Quantity: | |

Vacuum Suction Cups

Vacuum Suction Cups, also known as Vacuum Suction Pad, industrial suction cups, or Bellows Suction Cups, which are made from elastomeric silicone materials by silicone rubber compression & injection molding or LSR injection molds. Silicone Vacuum Suction Cup & Rubber Suction Pads, are main used to meet people’s daily hanging objects needs. But vacuum cups are also widely used in industries for handling sheet metal/wood, glass carrying, packing, and so on, can pick electronic components & panel, label or hold projects, open packaging bags, and also handle & transfer handle board, panels, concrete slabs etc.

Silicone Vacuum Suction Cups Materials Properties

Vacuum Suction Cup is non-toxic, tasteless

Silicone Suction Cup can resist high and low temperature, working temperature is from -40~230℃

Small Suction Pads made by silicone material is climatic resistance, ozone-resistance.

Silicone Vacuum Suction Cup has good physical property, harmless to the human body

Notes: Every coin has two sides, there is also disadvantages for the silicone material, its tear resistance, wear resistance is not good.

Vacuum Suction Cups Other Material

Vacuum Suction Cups can be made from a variety of materials. The material choice is based on the nature of the material handled, temperature, pressure, and frequency of operation. Elastomeric Molded Rubber Bellows materials are highly resistant to chemicals at high temperatures. However, the mechanical properties of elastomeric materials will be weakened at a higher temperature (above 150°F). The most used materials for the production of rubber bellows are the following:

Natural Rubber (NR)

Silicone Rubber: common silicone, FDA Food Grade Silicone, FDA Medical Grade Silicone, Liquid Silicone

Neoprene (CR)

Nitrile (NBR),

Viton,

Ethylene Propylene Diene Monomer (EPM/EPDM),

Styrene-Butadiene (SBR)

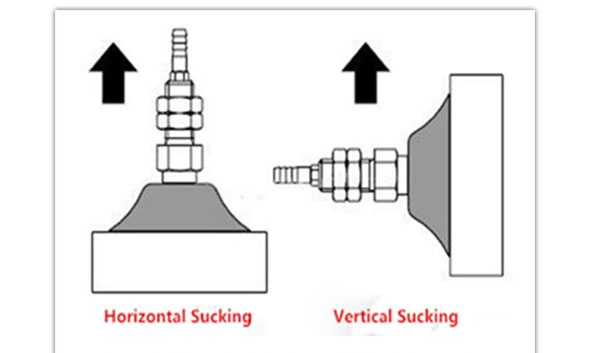

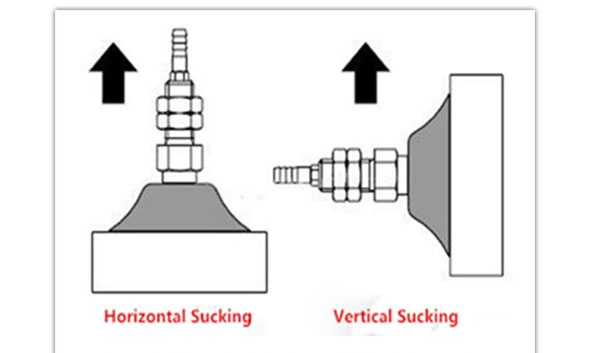

Connecting the elastomic rubber suction cups with the vacuum equipment via a elastomeric silicone rubber, plastic or metal tube, then attaching with the targeted-lifted objects like glass, panel, board or paper and trigger the vacuum equipment to suck or hook, which will produce negative pressure in silicone rubber vacuum cup and then it will start moving the targeted-lifted objects. When it has moved the targeted-lifted objects to the target place, vacuum suction equipment will smoothly inflated into the elastic rubber suction cup to change the negative pressure in elastic vacuum cup into zero pressure or a bit of positive pressure, then the silicone rubber vacuum cup will separate from the waited-lifted objects, then the moving objects task finished. Vacuum Suctions is widely used inindustrial suction cups equitment& mechanical arm, and also in our daily life.

Vacuum Suction Cups Major Defects in the market

Splitting & Bubbles Problem: This problem is mainly caused by Molding temperature & poor venting. If molding temperature is too high, air-venting is not good, and flashing of last mold doesn't clear thoroughly, splitting and bubbles problem will show up.

White Faded Marks problem was caused by silicone hose's material & mold tool's surface.

Uneven Wall Thickness: this problem mainly caused by mold tool, like mold-making precision, misalignment of upper mold and down mold, datum angle & the 4 located pins are not accurate enough.

Rubber Flashing is too big: to solve this problem, we need to pay attention to 3 points when production; the first one is mold-design, second one is workers' skill about removing flash, and the production technology is also very important, if molding pressure is not enough, will also make the flash hard to be removed.

Vacuum Suction Cup's Shape

● Round Suction Cups

● Flat Suction Cups

● Flat Concave Suction Cups

● Oval Flat Suction Cups

● Oval Concave Suction Cups

● Bellows Vacuum Cups

● Multibellows Suction Cups

● Deep Suction Cup

● Rectangular Suction Cups

● Rectangular Bellows Suction Cups

Vacuum Suction Cups Advanatage:

Easy to use: No matter what is sucked object material, as long as it can seal, air-proof, all can working. Electromagnetic chunk & suckers only working with metal matierals.

Not hurt to object components: Because Vacuum suctions cup is made from elastomer rubber materials, objects will not damange when sucking or lay down3. Environment friendly:Silicone Rubber Industial Suction Cups will not pollute the environment when working, also will not create light, heat or electromagnetism etc.

Our Production Advantage for Vacuum Suction Cups & Rubber Vacuum Pads

Precision Mold-Making Technology: such as silicone rubber compression molded parts can up to +/-0.02mm, small or mini flashing, parting line controls

One-stop Service: own mold-making, rubber compression molded, plastic injection molded, silicone & LSR injection molded production and simple assembly.

Professional Sales Teams and Quick Reply: Our sales engineers will well work together with mold designing department, production department and QC department etc, in aim to producing better qualified products & parts for customers

Free Design Analysis Support for Moldability and Manufacturability: we have two rich experience design engineers will cover your projects from ideas & drawings to end use.

Customer's Design Patent Protection: Only accepet custom-made projects according to customers design drawings or samples. Our company will not sell customer's products & parts to other customers & persons, as customers had paid mold-making cost to us and molding belong to their properties. We can sign NDA with customers.

Our Standard Vacuum Suction Cup/ Pad

Vacuum Suction Cups

Vacuum Suction Cups, also known as Vacuum Suction Pad, industrial suction cups, or Bellows Suction Cups, which are made from elastomeric silicone materials by silicone rubber compression & injection molding or LSR injection molds. Silicone Vacuum Suction Cup & Rubber Suction Pads, are main used to meet people’s daily hanging objects needs. But vacuum cups are also widely used in industries for handling sheet metal/wood, glass carrying, packing, and so on, can pick electronic components & panel, label or hold projects, open packaging bags, and also handle & transfer handle board, panels, concrete slabs etc.

Silicone Vacuum Suction Cups Materials Properties

Vacuum Suction Cup is non-toxic, tasteless

Silicone Suction Cup can resist high and low temperature, working temperature is from -40~230℃

Small Suction Pads made by silicone material is climatic resistance, ozone-resistance.

Silicone Vacuum Suction Cup has good physical property, harmless to the human body

Notes: Every coin has two sides, there is also disadvantages for the silicone material, its tear resistance, wear resistance is not good.

Vacuum Suction Cups Other Material

Vacuum Suction Cups can be made from a variety of materials. The material choice is based on the nature of the material handled, temperature, pressure, and frequency of operation. Elastomeric Molded Rubber Bellows materials are highly resistant to chemicals at high temperatures. However, the mechanical properties of elastomeric materials will be weakened at a higher temperature (above 150°F). The most used materials for the production of rubber bellows are the following:

Natural Rubber (NR)

Silicone Rubber: common silicone, FDA Food Grade Silicone, FDA Medical Grade Silicone, Liquid Silicone

Neoprene (CR)

Nitrile (NBR),

Viton,

Ethylene Propylene Diene Monomer (EPM/EPDM),

Styrene-Butadiene (SBR)

Connecting the elastomic rubber suction cups with the vacuum equipment via a elastomeric silicone rubber, plastic or metal tube, then attaching with the targeted-lifted objects like glass, panel, board or paper and trigger the vacuum equipment to suck or hook, which will produce negative pressure in silicone rubber vacuum cup and then it will start moving the targeted-lifted objects. When it has moved the targeted-lifted objects to the target place, vacuum suction equipment will smoothly inflated into the elastic rubber suction cup to change the negative pressure in elastic vacuum cup into zero pressure or a bit of positive pressure, then the silicone rubber vacuum cup will separate from the waited-lifted objects, then the moving objects task finished. Vacuum Suctions is widely used inindustrial suction cups equitment& mechanical arm, and also in our daily life.

Vacuum Suction Cups Major Defects in the market

Splitting & Bubbles Problem: This problem is mainly caused by Molding temperature & poor venting. If molding temperature is too high, air-venting is not good, and flashing of last mold doesn't clear thoroughly, splitting and bubbles problem will show up.

White Faded Marks problem was caused by silicone hose's material & mold tool's surface.

Uneven Wall Thickness: this problem mainly caused by mold tool, like mold-making precision, misalignment of upper mold and down mold, datum angle & the 4 located pins are not accurate enough.

Rubber Flashing is too big: to solve this problem, we need to pay attention to 3 points when production; the first one is mold-design, second one is workers' skill about removing flash, and the production technology is also very important, if molding pressure is not enough, will also make the flash hard to be removed.

Vacuum Suction Cup's Shape

● Round Suction Cups

● Flat Suction Cups

● Flat Concave Suction Cups

● Oval Flat Suction Cups

● Oval Concave Suction Cups

● Bellows Vacuum Cups

● Multibellows Suction Cups

● Deep Suction Cup

● Rectangular Suction Cups

● Rectangular Bellows Suction Cups

Vacuum Suction Cups Advanatage:

Easy to use: No matter what is sucked object material, as long as it can seal, air-proof, all can working. Electromagnetic chunk & suckers only working with metal matierals.

Not hurt to object components: Because Vacuum suctions cup is made from elastomer rubber materials, objects will not damange when sucking or lay down3. Environment friendly:Silicone Rubber Industial Suction Cups will not pollute the environment when working, also will not create light, heat or electromagnetism etc.

Our Production Advantage for Vacuum Suction Cups & Rubber Vacuum Pads

Precision Mold-Making Technology: such as silicone rubber compression molded parts can up to +/-0.02mm, small or mini flashing, parting line controls

One-stop Service: own mold-making, rubber compression molded, plastic injection molded, silicone & LSR injection molded production and simple assembly.

Professional Sales Teams and Quick Reply: Our sales engineers will well work together with mold designing department, production department and QC department etc, in aim to producing better qualified products & parts for customers

Free Design Analysis Support for Moldability and Manufacturability: we have two rich experience design engineers will cover your projects from ideas & drawings to end use.

Customer's Design Patent Protection: Only accepet custom-made projects according to customers design drawings or samples. Our company will not sell customer's products & parts to other customers & persons, as customers had paid mold-making cost to us and molding belong to their properties. We can sign NDA with customers.

Our Standard Vacuum Suction Cup/ Pad

Home | About Us | Contact Us | Products | News Center | LSR Injection Molding | Liquid Silicone Rubber | Silicone Bellows | Silicone Cover | Silicone Grommet | Silicone Nozzle | Silicone Plug | Silicone Sleeves | Sitemap | Silicone Keypad | Duckbill Valve | Umbrella Valve | Slit Valve | Membrane Valve | News | Silicone Valve | Rubber Valves Manufacturing Process | Silicone Valve Manufacturing Process | Request Quote | Silicone Rubber Sleeve | EPDM Grommet | Nitrile Grommet | Antibacterial Silicone | Silicone Suction Cup | Silicone Sleeve for Glass Bottle | One Way Rubber Valve | Rubber Duckbill Valve | Rubber Flapper Valve | Rubber Mushroom Valve | Company news | Profession news | Frequently Q&A | Liquid Silicone Rubber | silicone sleeve | Product inquiry