- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Hot: Umbrella Valve, Duckbill Valve, Flapper Valve, Silicone Valve & Rubber One Way Valve

ERB-1

Better

3924100000

| Availability: | |

|---|---|

| Quantity: | |

Neoprene Bellows

Neoprene Bellows, also known as, CR bellows, neoprene dust cover and neoprene expansion joints, are designed as a cover or expansion bellows which have versatile functions as silicone “dust boots” or seals, elastomeric expansion joint, used to seal out dust and other light-duty environmental factors while allowing a specific stroke or predetermined range of motion. They are quite common in industrial and automotive applications.

Neoprene Bellows are usually produced by silicone rubber compression molding, extrusion moulding or rubber injection moulding.

As for the Rubber Bellows, we have some types can be sold to you directly like our attached file shows, please check for details:

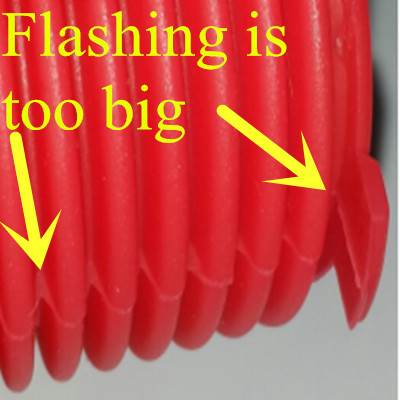

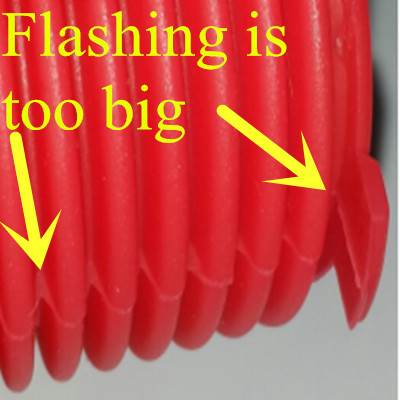

Reasons of Rubber Bellows' major defects:

1. Flashing is too big: to solve this problem, we need to pay attention to 3 points when production; the first one is mold-design, second one is workers' skill about removing flash, and the production technology is also very important, if molding pressure is not enough, will also make the flash hard to be removed.

2. Mold misalignment & uneven wall: this problem mainly caused by mold tool, like mold-making precision, misalignment of upper mold and down mold, datum angle & the 4 located pins are not accurate enough.

3. Lip cracking: the situation is relative to raw materials hardness & durometer, products' structure, and die-cutting tool.

Rubber Bellows Main Material

| Material | Abbreviation | Temperature Range | Aging Weathering, Ozone | Anti-Oil & Grease | Anti Water Swell | Flex-Fatigue | Economy of Material | Material Notes |

Chloroprene & Neoprene | CR | -40F to 250F | Good | Good | Average | Excellent | Good | Exprosure to refrigerants, can be compounded for FDA applications |

| Nitrile | NBR | -22F to 212F | Poor | Excellent | Good | Good | Excellent | Excellent resistance to petroleum based oils and hydrocarbon fuels |

| Ethylene-Propylene | EPDM EPM | -60F to 300F | Excellent | Poor | Excellent | Good | Excellent | / |

| Silicone | VMQ | -75F to 450F | Excellent | Average | Excellent | Excellent | Average | Medical and aerospace applications |

| Fluorocarbon | FKM | 5F to 390F | Excellent | Excellent | Good | Average | Poor | / |

Neoprene Bellows Shape

Miniature Rubber Bellows Tapered Rubber Bellows

Rubber Flange Bellows Square Rubber Bellows

Neoprene Bellows Properties:

Neoprene also known as choloprene, it is a common material used in rubber bellow and dust boot applications with many good performance:

1. Good oil & grease resistance

2. Good Tear Strength, compression & abrasion resistance

3. Excellent Refrigerants / Ammonia performance

4. Temperature Range (dry heat): -40F to 250F

While neoprene has poor cold & fuel resistance, if the rubber bellows requires good cold & fuel resistance, should use other material.

Our company advantage for Neoprene Bellows manufacturing process:

1. Precision Own Mold-making Technology since 1998:

2. In-depth knowledge of different elastomer rubber materials molded for rubber bellows, expansion joint & boots

3. Mature experience of flexible silicone rubber bellows quality controls:

a. Neoprene bellows wall thickness sizes telorance: less 0.05mm

b. mini or less expansion joint flashing

c. mold maintenance in aim to up and down mold plate with horizontal stripe in exact position

d. good ejected molding to improve silicone bellows production efficiency

4. Rapid prototyping with full sizes production equipment and production materials.

5. In-depth knowledge of overmolded metal + silicone rubber bellows production

Neoprene Bellows

Neoprene Bellows, also known as, CR bellows, neoprene dust cover and neoprene expansion joints, are designed as a cover or expansion bellows which have versatile functions as silicone “dust boots” or seals, elastomeric expansion joint, used to seal out dust and other light-duty environmental factors while allowing a specific stroke or predetermined range of motion. They are quite common in industrial and automotive applications.

Neoprene Bellows are usually produced by silicone rubber compression molding, extrusion moulding or rubber injection moulding.

As for the Rubber Bellows, we have some types can be sold to you directly like our attached file shows, please check for details:

Reasons of Rubber Bellows' major defects:

1. Flashing is too big: to solve this problem, we need to pay attention to 3 points when production; the first one is mold-design, second one is workers' skill about removing flash, and the production technology is also very important, if molding pressure is not enough, will also make the flash hard to be removed.

2. Mold misalignment & uneven wall: this problem mainly caused by mold tool, like mold-making precision, misalignment of upper mold and down mold, datum angle & the 4 located pins are not accurate enough.

3. Lip cracking: the situation is relative to raw materials hardness & durometer, products' structure, and die-cutting tool.

Rubber Bellows Main Material

| Material | Abbreviation | Temperature Range | Aging Weathering, Ozone | Anti-Oil & Grease | Anti Water Swell | Flex-Fatigue | Economy of Material | Material Notes |

Chloroprene & Neoprene | CR | -40F to 250F | Good | Good | Average | Excellent | Good | Exprosure to refrigerants, can be compounded for FDA applications |

| Nitrile | NBR | -22F to 212F | Poor | Excellent | Good | Good | Excellent | Excellent resistance to petroleum based oils and hydrocarbon fuels |

| Ethylene-Propylene | EPDM EPM | -60F to 300F | Excellent | Poor | Excellent | Good | Excellent | / |

| Silicone | VMQ | -75F to 450F | Excellent | Average | Excellent | Excellent | Average | Medical and aerospace applications |

| Fluorocarbon | FKM | 5F to 390F | Excellent | Excellent | Good | Average | Poor | / |

Neoprene Bellows Shape

Miniature Rubber Bellows Tapered Rubber Bellows

Rubber Flange Bellows Square Rubber Bellows

Neoprene Bellows Properties:

Neoprene also known as choloprene, it is a common material used in rubber bellow and dust boot applications with many good performance:

1. Good oil & grease resistance

2. Good Tear Strength, compression & abrasion resistance

3. Excellent Refrigerants / Ammonia performance

4. Temperature Range (dry heat): -40F to 250F

While neoprene has poor cold & fuel resistance, if the rubber bellows requires good cold & fuel resistance, should use other material.

Our company advantage for Neoprene Bellows manufacturing process:

1. Precision Own Mold-making Technology since 1998:

2. In-depth knowledge of different elastomer rubber materials molded for rubber bellows, expansion joint & boots

3. Mature experience of flexible silicone rubber bellows quality controls:

a. Neoprene bellows wall thickness sizes telorance: less 0.05mm

b. mini or less expansion joint flashing

c. mold maintenance in aim to up and down mold plate with horizontal stripe in exact position

d. good ejected molding to improve silicone bellows production efficiency

4. Rapid prototyping with full sizes production equipment and production materials.

5. In-depth knowledge of overmolded metal + silicone rubber bellows production

Home | About Us | Contact Us | Products | News Center | LSR Injection Molding | Liquid Silicone Rubber | Silicone Bellows | Silicone Cover | Silicone Grommet | Silicone Nozzle | Silicone Plug | Silicone Sleeves | Sitemap | Silicone Keypad | Duckbill Valve | Umbrella Valve | Slit Valve | Membrane Valve | News | Silicone Valve | Rubber Valves Manufacturing Process | Silicone Valve Manufacturing Process | Request Quote | Silicone Rubber Sleeve | EPDM Grommet | Nitrile Grommet | Antibacterial Silicone | Silicone Suction Cup | Silicone Sleeve for Glass Bottle | One Way Rubber Valve | Rubber Duckbill Valve | Rubber Flapper Valve | Rubber Mushroom Valve | Company news | Profession news | Frequently Q&A | Liquid Silicone Rubber | silicone sleeve | Product inquiry