- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Hot: Umbrella Valve, Duckbill Valve, Flapper Valve, Silicone Valve & Rubber One Way Valve

| Availability: | |

|---|---|

| Quantity: | |

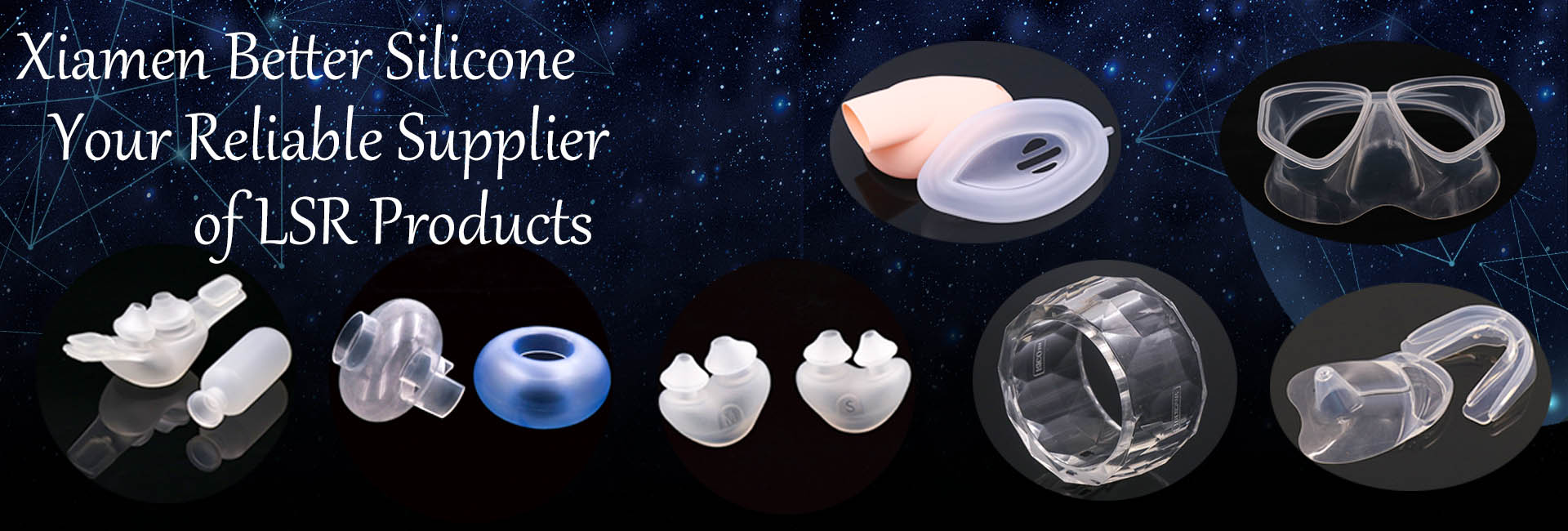

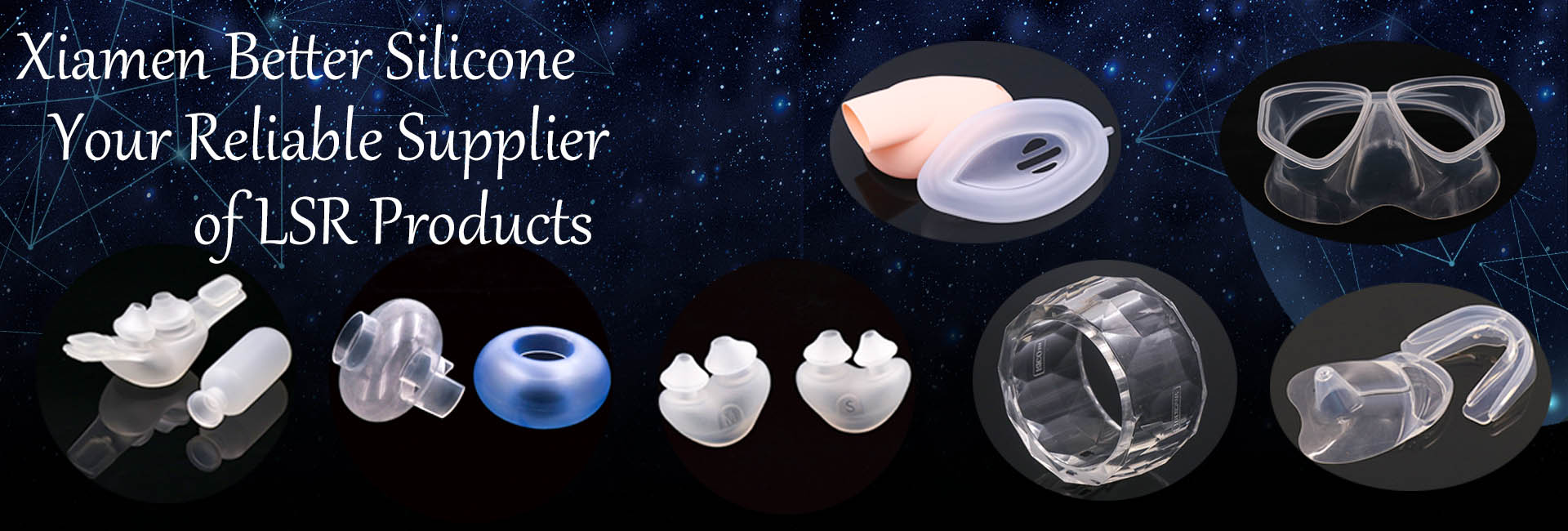

Liquid Silicone Rubber Injection Molding

Liquid Injection Molding, also known as Liquid Silicone Molding & Liquid Silicone Rubber Molding, which is also called Liquid Silicone Rubber Injection Molding and Liquid Silicone Mold which is used to produce liquid silicone rubber seal, LSR baby products or medical & infant products by Liquid silicon injection moudling machines. Like LSR Mask Cushion, LSR Menstrual Cup, LSR Baby Nipple, LSR Forehead Pad, LSR Breast pump, etc. If use liquid silicone rubber injection mold production, it will be safer, preciser & more environmentally friendly & transparent, using less manpower, and having high production efficiency compared with silicone rubber compression mold.

Liquid Silicone Rubber Injection Molding Material

Liquid Injection Molding material, Liquid Silicone Rubber, it is paste-like, non-yellowing and easily pigmentable two-component compounds with short curing times. Their vulcanizates are noted for their high transparency and excellent mechanical properties. This series is specially desinged for the Baby Care application field ! The material can be FDA Food Grade Silicone, FDA Medical Grade Silicone, and it is a inorganic nature, which is clean, plasticizer-free, tasteless, odorless, is resistant to bacteria growth, and will not stain or corrode other materials.is relative to solid vulcanized silicone rubber, it is a liquid rubber, which has good mobility, faster vulcanization speed, safer and more environmental-friendly, can fully meet the requirements of food grade. These grades are particularly suitable for the economical production of large series of injection molded articles. Postcured parts can be used for applications in the pharmaceutical and food industries and comply with the recommendations “XV. Silicone” of the BfR and FDA § 177.2600.

Liquid silicone rubber has excellent transparency, anti-tearing strength, resilience, anti-yellowing, thermal stability, water resistance, good air permeability, heat resistance and aging resistance and weather resistance, at the same time, moderate viscosity, easy to operate, can produce high transparency products.

We have molding technology for Liquid Silicone Rubber (LSR) from 0 to 80 shore A. We can use liquid silicone rubber to overmold plastic, metal inserts and special materials. LSR products can be widely used in baby products, medical supplies, food grade kitchen products, automobile parts, and electronic products.

The finishedLSR Injection Mold tool is loaded into an advanced LSR-specific injection molding press that is precision geared for accurate control of shot size to produce the most consistent LSR parts. Since LSR is a thermosetting polymer, its molded state is permanent—once it is set, it can’t be melted again like a thermoplastic. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Liquid Silicone Rubber Injection Molding Machine

Vertical LSR Injection Moulding Machine Horzontal LSR Injection Moulding Machine

Liquid Silicone Rubber Injection Molding Parts

Liquid Silicone Rubber Mask Cushion is a part of CPAP Nasal Masks and CPAP Full Face Masks. This replacement CPAP Mask Cushion is designed to rest between the CPAP plastic frame and user's face.

Liquid Silicone Rubber Forehead Pad is a part of CPAP nasal masks and CPAP full face masks. The LSR Silicone forehead pad is designed to improve the user’s using experience, which is placed between the CPAP mask and user's forehead. It is also called Forehead Pad, Silicone Cushion. The forehead pad can attach to the support bracket near the top of the mask's headgear. The pad can be configured easily by simply pressing the gel into the bracket tabs at the appropriate angle.

Medical Grade Liquid Silicone Menstrual Cup made by LSR Injection Mold can have minimum parting line, which is almost invisible, and also flashing will be quite small. LSR Menstrual cup material can meet all food grade and medical requirements or certifications, like USP Class VI, FDA 21 CFR 177.2600, BfR XV etc. Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids.

Liquid Silicone Rubber Baby Nipple, due to the liquid nature of the material, is easy to get flash. So, LSR Injection molds for LSR molding needs a super high precision mold making skill to complete this molding parts job with flashless or less goal.

Liquid Silicone Rubber Injection Molding Order Process

Liquid Silicone Rubber Injection Molding Period:

Customers send details for inquiry, like 2D drawing & 3D drawing (Stp/IGS format), samples or photos with specific dimensions

Engineer provides technical evaluation & suggestion

Manager provides quotation

Order confirmed:

Order confirmation

Mold design layout preparation

Mold design layout approval

Mold Making:

Steel ordering

Mold making

Mold assembly

Liquid Silicone Rubber Injection Molding Manufacture Advantages

One-stop Service: own mold-making, rubber compression molded, plastic injection molded, silicone & LSR injection molded production and simple assembly.

Professional Sales Teams and Quick Reply: Our sales engineers will well work together with mold designing department, production department and QC department etc, in aim to producing better qualified products & parts for customers

Free Design Analysis Support for Moldability and Manufacturability: we have two rich experience design engineers will cover your projects from ideas & drawings to end use.

Customer's Design Patent Protection: Only accepet custom-made projects according to customers design drawings or samples. Our company will not sell customer's products & parts to other customers & persons, as customers had paid mold-making cost to us and molding belong to their properties. We can sign NDA with customers.

Liquid Silicone Rubber Injection Molding

Liquid Injection Molding, also known as Liquid Silicone Molding & Liquid Silicone Rubber Molding, which is also called Liquid Silicone Rubber Injection Molding and Liquid Silicone Mold which is used to produce liquid silicone rubber seal, LSR baby products or medical & infant products by Liquid silicon injection moudling machines. Like LSR Mask Cushion, LSR Menstrual Cup, LSR Baby Nipple, LSR Forehead Pad, LSR Breast pump, etc. If use liquid silicone rubber injection mold production, it will be safer, preciser & more environmentally friendly & transparent, using less manpower, and having high production efficiency compared with silicone rubber compression mold.

Liquid Silicone Rubber Injection Molding Material

Liquid Injection Molding material, Liquid Silicone Rubber, it is paste-like, non-yellowing and easily pigmentable two-component compounds with short curing times. Their vulcanizates are noted for their high transparency and excellent mechanical properties. This series is specially desinged for the Baby Care application field ! The material can be FDA Food Grade Silicone, FDA Medical Grade Silicone, and it is a inorganic nature, which is clean, plasticizer-free, tasteless, odorless, is resistant to bacteria growth, and will not stain or corrode other materials.is relative to solid vulcanized silicone rubber, it is a liquid rubber, which has good mobility, faster vulcanization speed, safer and more environmental-friendly, can fully meet the requirements of food grade. These grades are particularly suitable for the economical production of large series of injection molded articles. Postcured parts can be used for applications in the pharmaceutical and food industries and comply with the recommendations “XV. Silicone” of the BfR and FDA § 177.2600.

Liquid silicone rubber has excellent transparency, anti-tearing strength, resilience, anti-yellowing, thermal stability, water resistance, good air permeability, heat resistance and aging resistance and weather resistance, at the same time, moderate viscosity, easy to operate, can produce high transparency products.

We have molding technology for Liquid Silicone Rubber (LSR) from 0 to 80 shore A. We can use liquid silicone rubber to overmold plastic, metal inserts and special materials. LSR products can be widely used in baby products, medical supplies, food grade kitchen products, automobile parts, and electronic products.

The finishedLSR Injection Mold tool is loaded into an advanced LSR-specific injection molding press that is precision geared for accurate control of shot size to produce the most consistent LSR parts. Since LSR is a thermosetting polymer, its molded state is permanent—once it is set, it can’t be melted again like a thermoplastic. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Liquid Silicone Rubber Injection Molding Machine

Vertical LSR Injection Moulding Machine Horzontal LSR Injection Moulding Machine

Liquid Silicone Rubber Injection Molding Parts

Liquid Silicone Rubber Mask Cushion is a part of CPAP Nasal Masks and CPAP Full Face Masks. This replacement CPAP Mask Cushion is designed to rest between the CPAP plastic frame and user's face.

Liquid Silicone Rubber Forehead Pad is a part of CPAP nasal masks and CPAP full face masks. The LSR Silicone forehead pad is designed to improve the user’s using experience, which is placed between the CPAP mask and user's forehead. It is also called Forehead Pad, Silicone Cushion. The forehead pad can attach to the support bracket near the top of the mask's headgear. The pad can be configured easily by simply pressing the gel into the bracket tabs at the appropriate angle.

Medical Grade Liquid Silicone Menstrual Cup made by LSR Injection Mold can have minimum parting line, which is almost invisible, and also flashing will be quite small. LSR Menstrual cup material can meet all food grade and medical requirements or certifications, like USP Class VI, FDA 21 CFR 177.2600, BfR XV etc. Under extensive testing, liquid silicone rubber has demonstrated superior compatibility with human tissue and body fluids.

Liquid Silicone Rubber Baby Nipple, due to the liquid nature of the material, is easy to get flash. So, LSR Injection molds for LSR molding needs a super high precision mold making skill to complete this molding parts job with flashless or less goal.

Liquid Silicone Rubber Injection Molding Order Process

Liquid Silicone Rubber Injection Molding Period:

Customers send details for inquiry, like 2D drawing & 3D drawing (Stp/IGS format), samples or photos with specific dimensions

Engineer provides technical evaluation & suggestion

Manager provides quotation

Order confirmed:

Order confirmation

Mold design layout preparation

Mold design layout approval

Mold Making:

Steel ordering

Mold making

Mold assembly

Liquid Silicone Rubber Injection Molding Manufacture Advantages

One-stop Service: own mold-making, rubber compression molded, plastic injection molded, silicone & LSR injection molded production and simple assembly.

Professional Sales Teams and Quick Reply: Our sales engineers will well work together with mold designing department, production department and QC department etc, in aim to producing better qualified products & parts for customers

Free Design Analysis Support for Moldability and Manufacturability: we have two rich experience design engineers will cover your projects from ideas & drawings to end use.

Customer's Design Patent Protection: Only accepet custom-made projects according to customers design drawings or samples. Our company will not sell customer's products & parts to other customers & persons, as customers had paid mold-making cost to us and molding belong to their properties. We can sign NDA with customers.

Home | About Us | Contact Us | Products | News Center | LSR Injection Molding | Liquid Silicone Rubber | Silicone Bellows | Silicone Cover | Silicone Grommet | Silicone Nozzle | Silicone Plug | Silicone Sleeves | Sitemap | Silicone Keypad | Duckbill Valve | Umbrella Valve | Slit Valve | Membrane Valve | News | Silicone Valve | Rubber Valves Manufacturing Process | Silicone Valve Manufacturing Process | Request Quote | Silicone Rubber Sleeve | EPDM Grommet | Nitrile Grommet | Antibacterial Silicone | Silicone Suction Cup | Silicone Sleeve for Glass Bottle | One Way Rubber Valve | Rubber Duckbill Valve | Rubber Flapper Valve | Rubber Mushroom Valve | Company news | Profession news | Frequently Q&A | Liquid Silicone Rubber | silicone sleeve | Product inquiry